Schneider Electric Driver

Dublin, Feb. 01, 2021 (GLOBE NEWSWIRE) -- The 'Predictive Maintenance Market Analysis, By Component Type, By Deployment Type, By Organization Size, By Application, Forecast to 2027' report has been added to ResearchAndMarkets.com's offering.

Global Predictive Maintenance Market was valued at USD 2.94 Billion in 2019 and is expected to reach USD 21.20 Billion by the year 2027, at a CAGR of 28.9%.

The rising need for analytics tools to derive actionable insights from gathered data, the reduced computational time that enables a faster course of action, increased efficiency, and constant innovation are some factors driving the market growth.

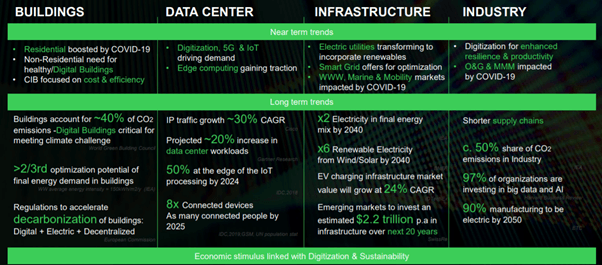

Owing to rising urbanization and digitalization across the world, end-user sectors like manufacturing, healthcare, and transport have experienced growth and now rely on technology-driven systems for operation.

Predictive maintenance is one such technique that is widely employed by organizations. These autonomous systems help the collection and analysis of raw data about performance factors of various operations carried out in those industries. They aid in predicting the failure time of different components of a machine, which helps in preventing a complete operational halt and reduces maintenance time. The rising need for analytics tools to derive actionable insights from gathered data, reduced computational time, increased efficiency, and a decrease in operation & maintenance costs and asset downtime are the factors driving the growth of the predictive maintenance market.

The growth of the predictive maintenance market is expected to be restrained by low awareness regarding the use of predictive maintenance and the high operational and maintenance costs of these systems. It is anticipated that extensive research and development funded by various companies and governments would help in overcoming this challenge and convert it into an opportunity for the predictive maintenance market to thrive.

The paramount importance of confidentiality and secrecy in the operation of many government and private companies is expected to expand the size of the predictive maintenance market. Market players are adopting various growth strategies to expand their offerings. This includes new product developments, mergers and acquisitions, partnerships, agreements, and business expansions. Predictive maintenance solutions offer numerous benefits to enterprises, such as lower maintenance costs, reduced machine failures, lesser downtime for repairs, reduced stock of spare parts, increased production, verification of repairs, increased service life of parts, and improved operator safety.

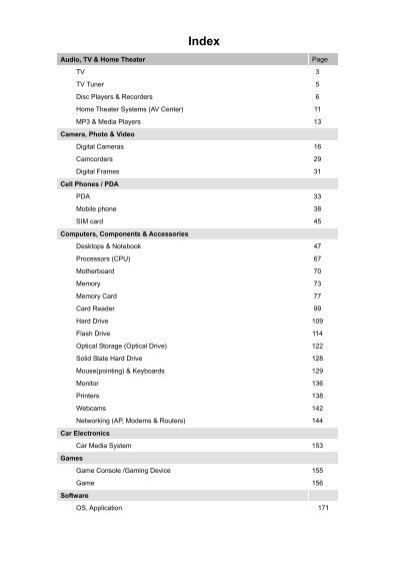

Key Topics Covered:

Chapter 1. Market Synopsis

1.1. Market Definition

1.2. Research Scope & Premise

1.3. Methodology

1.4. Market Estimation Technique

Chapter 2. Executive Summary

2.1. Summary Snapshot, 2018 - 2026

Chapter 3. Indicative Metrics

3.1. Increasing adoption of analytical tools.

3.2. Rise in data generation and data storage globally.

Chapter 4. Predictive Maintenance Segmentation & Impact Analysis

4.1. Predictive Maintenance Segmentation Analysis

4.2. Predictive Maintenance Market Value Chain Analysis, 2016-2026

4.3. Regulatory framework

4.4. Predictive Maintenance Market Impact Analysis

4.4.1. Market driver analysis

4.4.1.1. Rising need of analytic tools to derive actionable insights from gathered data.

4.4.1.2. Reduce computational time enabling faster course of action

4.4.1.3. Increased efficiency, decrease in operation & maintenance costs and asset downtime.

4.4.2. Market restraint analysis

4.4.2.1. Low awareness regarding the benefits of using Predictive Maintenance Systems.

4.5. Key opportunities prioritized

4.6. Predictive Maintenance Pricing Analysis

Chapter 5. Predictive Maintenance Market by Component Type Insights & Trends

5.1. Predictive Maintenance Component Type dynamics & Market Share, 2018 & 2026

5.2. Solutions

5.3. Services

Chapter 6. Predictive Maintenance Market by Deployment type Industry Insights & Trends

6.1. Predictive Maintenance Deployment dynamics & Market Share, 2018 & 2026

6.2. On-premises

6.3. Cloud

Chapter 7. Predictive Maintenance Market by Organization Size type Industry Insights & Trends

7.1. Predictive Maintenance Deployment dynamics & Market Share, 2018 & 2026

7.2. Large Enterprises

7.3. Small and Medium Enterprises

Chapter 8. Predictive Maintenance Market by End User Industry Insights & Trends

8.1. Predictive Maintenance End User dynamics & Market Share, 2018 & 2026

8.2. Manufacturing

8.3. Energy and Utilities

8.4. Healthcare

8.5. Government

8.6. Transport and Logistics

Chapter 9. Predictive Maintenance Market Regional Outlook

9.1. Predictive Maintenance Market share by region, 2018 & 2026

Cinterion wireless modules driver. Chapter 10. Competitive Landscape

10.1. Market Revenue Share by Manufacturers

10.2. Manufacturing Cost breakdown Analysis

10.3. Mergers & Acquisitions

10.4. Strategy benchmarking

10.5. Vendor Landscape

Chapter 11. Company Profiles

- Schneider Electric Driver Manager

- Schneider Electric Drivers

- Schneider Electric Driver Pack V2.6 Download

- Schneider Electric Driver Download

- IBM

- Microsoft

- SAP

- GE

- Schneider Electric

- Hitachi

- PTC

- Software AG

- SAS

- TIBCO

For more information about this report visit https://www.researchandmarkets.com/r/fc3zqb

Schneider Electric Driver Manager

Research and Markets also offers Custom Research services providing focused, comprehensive and tailored research.

- The Conext™ Configuration tool is used by system installers to simplify the task of system configuration and reduce installation time. It’s a PC-based software tool that works on systems that include the Conext™ XW Pro, XW+, SW, and peripherals.

- One key driver in this new market paradigm is the massive success of voice-activated devices. The interior of Schneider Electric's new integrated electrical panel. (Credit: Schneider Electric).

Schneider Electric Drivers

Introducing the new Schneider Electric Centeron 4G LTE Cellular Radar Monitor. This monitor uses guided wave technology and is an intrinsically safe USL and CNL certified product for monitoring above-ground tanks up to 20’ in height. The radar monitor provides levels accurate to +/-.05%.

Schneider Electric Driver Pack V2.6 Download